There is still some work to be done to make this process cost-effective. Stefan Höller, Managing Director and the resourceful mind behind Hoeller Elektrolyzer, wants to change that. “With our stack, you're going to be able to produce hydrogen in a way that's so inexpensive it's so far been thought impossible,” he said.

This is no accident, because over 25 years of expertise and pioneering work by company founder Stefan Höller have gone into the Hoeller stack. He has continuously refined his technology and holds several patents on it – always with the aim of reducing the production cost of green hydrogen. The innovative design of the cells and stack boosts its efficiency. The stack also uses significantly less platinum and iridium than usual, and a higher output pressure makes it even more powerful.

Anything but pie-in-the-sky

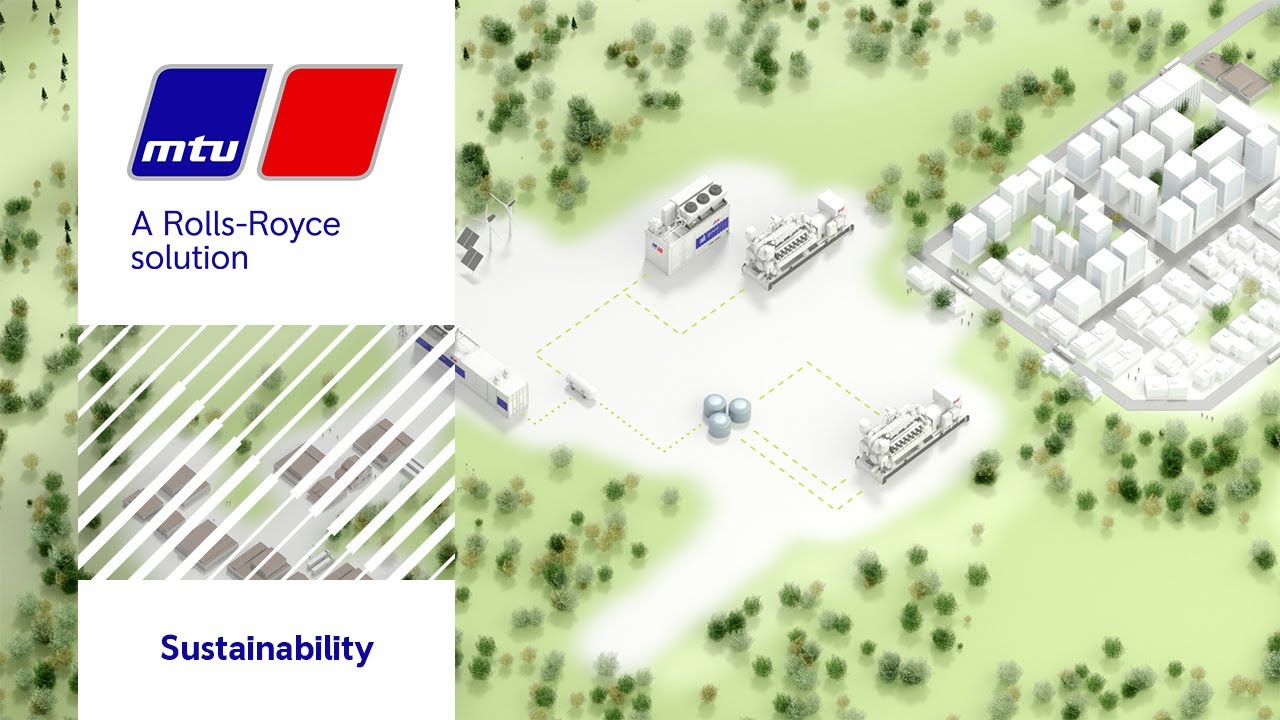

It won't be long until the first mtu electrolyzer is producing hydrogen. Development work on the first mtu electrolyzer using a Hoeller stack has been underway for some time. It is set to go into operation at the Validation Center in Friedrichshafen in 2023, showing the part an electrolyzer can play in the overall architecture of a microgrid. An initial customer project is already planned for 2024. “We're going to be launching electrolyzers with several megawatts of power right from the word go. A total output of over 100 MW is conceivable by combining several electrolyzers,” said Armin Fürderer.

Rolls-Royce and Hoeller combining their strengths

Rolls-Royce Power Systems and Hoeller Elektrolyzer are ideal partners, with Hoeller developing the specialist technology of the electrolysis stack and Rolls-Royce using it to develop the complete electrolyzer, initially housed in containers. Rolls-Royce's global sales and service network will ensure access to a wide range of customers across the world. Discussions with the first customers are already underway, with the first customer projects expected to kick off in 2024 – all aimed at making hydrogen green, its production economical and the future climate-friendly.